Waterproof webbing is made of two materials. The core of the webbing consists of a PVC fabric over which a layer of thermoplastic polyurethane (TPU) is applied. The combination of the two materials gives the webbing those unique features that you will find so useful. See for yourself how easy it is to work with this stuff.

Characteristics of waterproof webbing

Flexible and pleasant to touch polyurethane protects the strong PVC core fabric. The TPU ensures resistance to water, chemicals, sweat, bacteria, UV radiation, and weather. The antibacterial surface is well-accepted by animals. It does not get abraded and its properties are stable at low and high temperatures alike. The webbing meets the requirements for receiving the REACH and ROHS certificates.

A great advantage of waterproof webbing is easy maintenance – it can be cleaned with soap and water. Despite its thickness, the webbing is soft and flexible.

This is the most modern replacement for leather. Its main use is for making dog collars and leashes, harness, halters and lunge lines for horses, and manufacture of sporting goods, particularly belts – safety, military, or fashion belts for both men and women.

If you use stainless steel or brass hardware, you will produce high-quality, long-lasting items that will be resistant to water, sweat, or chemicals, and will keep these properties for a very long time.

Cutting and holing the waterproof webbing

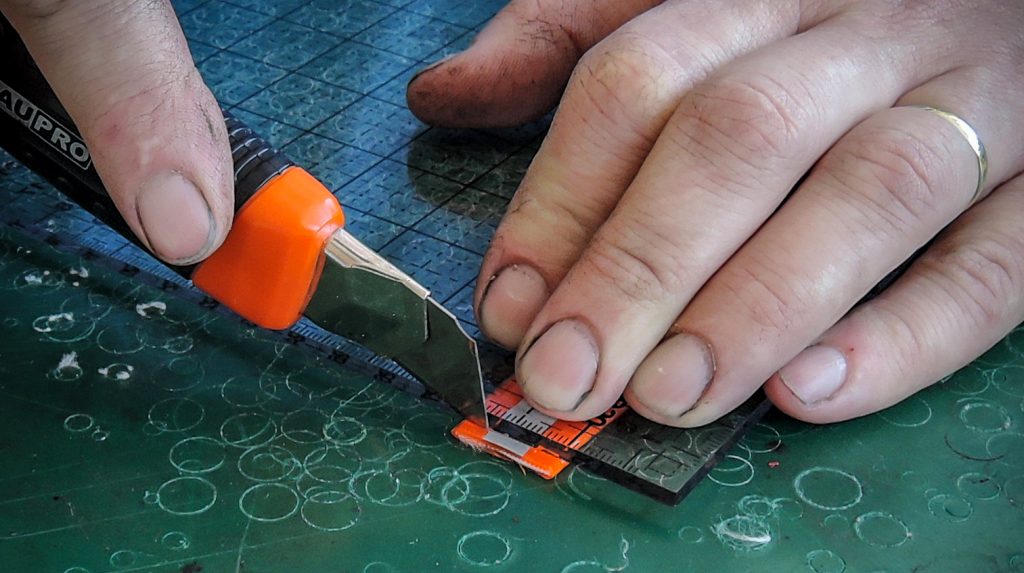

- cutting the webbing with a box cutter

- cutting straight, round and slant ends with scissors

- cutting a decorative tip using a strap end punch

The webbing can be easily cut with a knife or sharp scissors. Force is needed when cutting with a utility knife, (similar to cutting leather). The cut is smooth and free of burrs. Unlike classic polypropylene webbing, waterproof webbing straps can be easily trimmed into round and decorative tips.

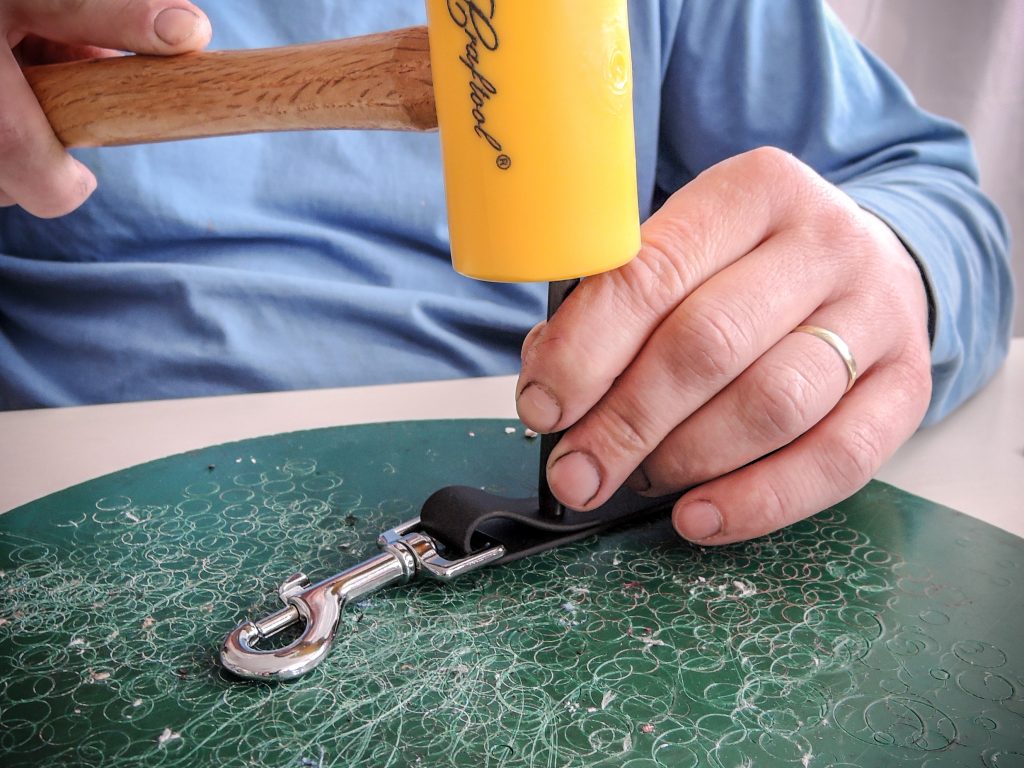

Riveting the waterproof webbing

Riveting is the easiest, fastest, and most commonly used way to join two lengths of waterproof webbing. The riveting procedure is reviewed in our earlier article on How to Master Manual Riveting.

The punched hole is free of burrs and keeps the desired undistorted shape. Classic polypropylene webbing can not be punched by hand punches.

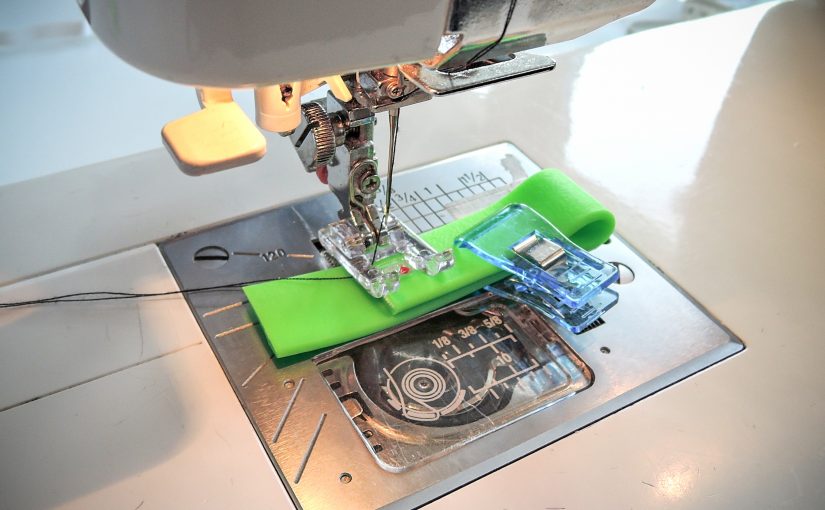

Sewing waterproof webbing

Waterproof webbing, like classic polypropylene (PP) or cotton webbing, can be decorated and/or joined together by stitching. Two layers of waterproof webbing are easily sewn together on an industrial sewing machine or even with a classic (metal) home sewing machine.

When sewing on a hobby machine, it is necessary to increase the tension of the upper thread and use a stronger needle, number 100-120, or use a special denim or leather sewing needle.

Can you recommend a thread use of sewing it?

Polyester bonded thread – Your go-to option. Strong, UV-resistant, and handles moisture like a champ.

Look for:

Nylon bonded thread – Also strong and flexible, but less UV-resistant than polyester. Only use if UV exposure is minimal.

PTFE thread (e.g. Gore Tenara) – Top-shelf stuff. Insanely durable, won’t degrade in sun, rain or salt. But it’s pricey and a bit tricky to sew.