Riveting is the joining of materials, whose aim is the quick formation of a firm, elastic and undetachable joint besides some exceptions. This is performed with the aid of metal saddlery rivets. An undetachable joint means that the dismantling of the rivet is only possible through the depreciation of the links (by breaking the head). Riveting is a non-demanding technological operation that needs more work tools. The quality rendering of the riveted links and quality fancy goods, point to the skill and professionalism of the manufacturer.

Function of saddlery rivets

- Connection – when we combine the individual components of the product together with rivets. Previously they were thus produced mostly for cardboard suitcases, nowadays more riveting replacing stitching. In terms of strength riveting is considered for 100% connection. New surface finishes for rivets (stainless steel, without nickel surface finish – see below) allows a more massive and more varied use of rivets. In the “Riveted Leash” article you will find simple instructions on how to produce a leash with the aid of rivets. The advantage of riveted leashes is higher connection strength, faster production and in particular the leash being able to withstand a higher strain. Regarding leashes for medium and large breed dogs you do not have to painstakingly duplicate sewing and sew brackets.

- Strengthening – Supplementary connecting technology. The components are pre-assembled by stitching, gluing and welding, and in a place with maximum strain a joint is additionally reinforced with a rivet.

- Ornamental – rivet created for the production of ornamental elements. This is used primarily in rhinestone rivets, pyramids and other decorative rivets.

Classifying of saddlery rivets

- Full rivets – used for connecting metal parts and components

- Hollow rivets – exclusively used for fancy goods, footwear and saddlery production. After unriveting hollow rivets have less internal stress than full rivets.

- one-piece hollow rivets – used for fastening skates to skating shoes, and in connecting clamps in fancy goods.

- two-piece hollow rivets

- two-piece closed hollow rivets (heads from both sides)

- without bite

- with bite

- two-piece open hollow rivets

- without bite

- with bite

- two-piece closed hollow rivets (heads from both sides)

Two-piece fancy rivets

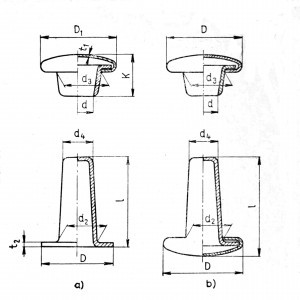

a – closed saddlery rivets, b – open saddlery rivets

Two-piece fancy rivets consist of a head and a shank. The rivet’s shank has a conical shape. In open saddlery rivets the cone is open at one end. In closed rivets the wider end of the cone is a closed head. The head and lower part of the rivet’s shank are the same. The riveted connection thus has the same appearance on both sides.

a – open rivet, b – closed rivet l – shank height, t2 – rivet’s wall thickness D – width of head, d2 – maximum width of shank

Rivet size

The main parameter for the proper selection of a rivet is the shank height. The so-called length of the clamping connection L, which corresponds to the thickness of the connected materials. At a low L height the shank end in the head is not sufficiently sealed. The joint is not solid and in time the rivet head loosens and falls off. If on the contrary the height of the rivet is substantial, during riveting the deformation of the shank will occur. The bearing surfaces of the head and also the rivet do not abut the material and the joint has a visible visual defect.

With or without bite

A bite is a depression or intentional distortion on the shank. A bite is very useful when riveting. It keeps the rivet head on the shank and enables to catch the rivet onto the connection, subsequently performing the riveting of all rivets at once. It is very practical and accelerates the riveting process, especially for belts, collars, harnesses and draw cords. When using a rivet with a bite, a riveted joint has slightly greater strength. In our offer of rivets you will find only open bite rivets.

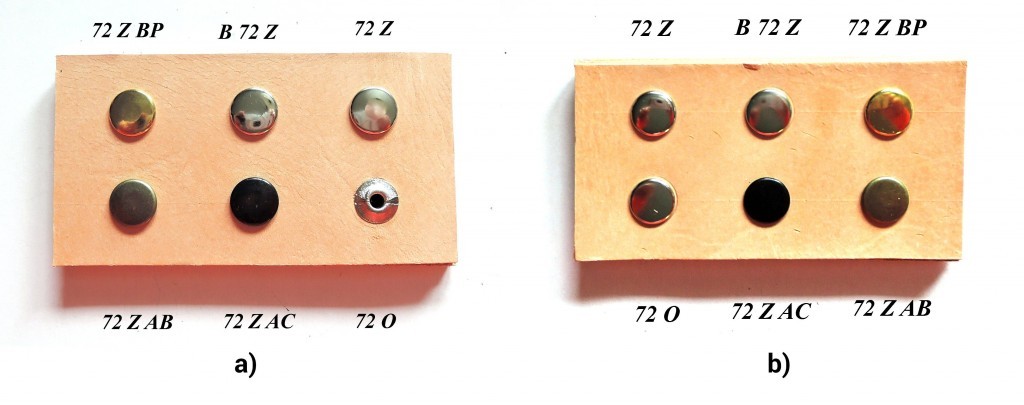

Saddlery rivets a – with bite, b – without bite

Using a two-piece fancy rivet

Two-piece open rivets are used where both sides of the rivet are not visible (belts, bags, leather and metal studs, briefcase springs, …).

Two-piece closed rivets are used where both sides of the rivet are visible or the rivet is in contact with another surface (bag straps, handles, leashes, collars, harnesses, suitcases…). It is appropriate to use a closed rivet for harnesses and leashes. With a constant dynamic tensile load on a collar or harness with an open rivet, the underside of the rivet’s cone may be deformed and this can lead to scratching the animal.

Two-piece saddlery rivets a – underside, b – front side 72 Z BP, B72 Z, 72 Z, 72 Z AB, 72 Z AC, 72 O

To be continued …

In the next part of our series on saddlery rivets you will learn what kinds of saddlery rivets you can find in our offer, how they differ from each other and for what they are best suited.

Pethardware.com

The only shop you’ll ever need for crafting collars and leashes.

Visit Pethardware.com